& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

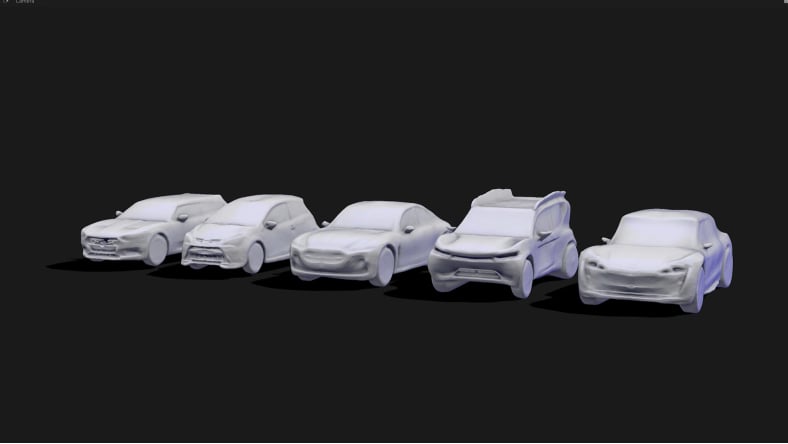

Artificial intelligence plays a pivotal role in the digital transformation of manufacturing by helping to make work faster and more efficient. It automates repetitive tasks, improves design quality, and streamlines production processes to save time and money. For example, AI can automate Computer-Aided Manufacturing (CAM) tasks, reducing errors and speeding up production times. AI can also be employed in the automotive industry, automating the optimization of a vehicle's aerodynamics and structural integrity while maintaining aesthetic and functional requirements. This frees up engineers and designers to concentrate on innovation, accelerating the launch of new and improved products.

AI can streamline manufacturing processes by automating repetitive tasks, reducing human error, and decreasing production time.

By improving efficiency, reducing waste, and minimizing downtime, AI can significantly reduce operational costs in manufacturing.

AI in manufacturing can improve product quality by using machine vision to detect known issues and inconsistencies in real-time during the manufacturing process.

AI in manufacturing can be used to address sustainability concerns, mitigate supply chain disruptions, and optimize resource use.

For over a decade, Autodesk has prioritized investment in AI because we recognize its transformative power for the Design & Make industry. Autodesk AI is technology that allows for creative exploration and better problem-solving, automates tedious and repetitive tasks, and provides actionable insights to end users when faced with overwhelming amounts of complex data.

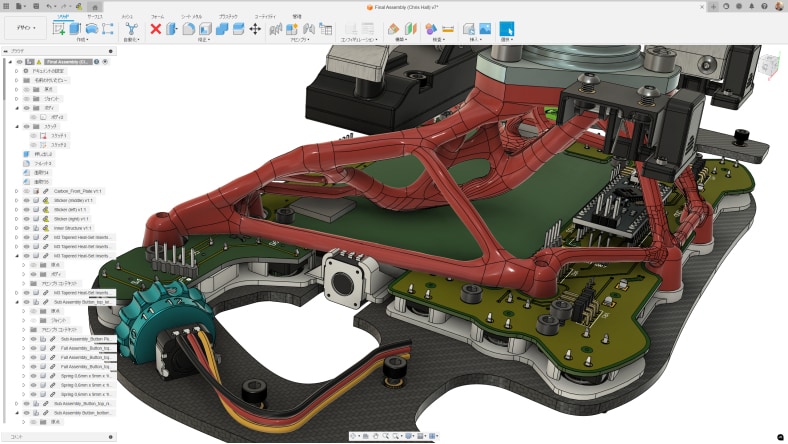

Autodesk Fusion

Generate manufacturing-ready design alternatives with your requirements, constraints, materials, and manufacturing options using generative design.

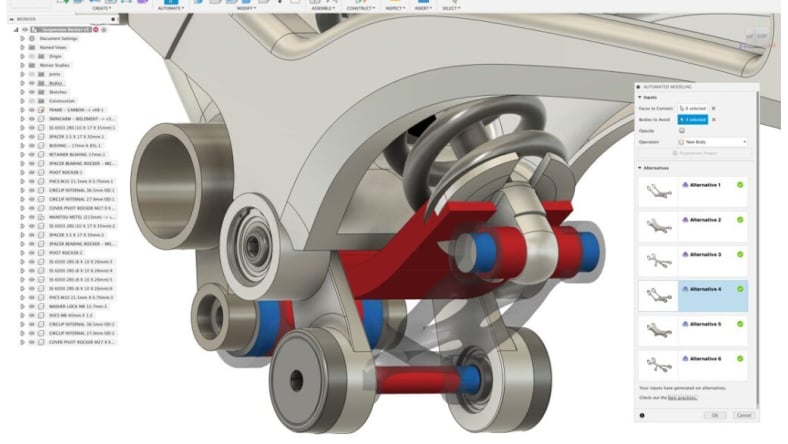

Autodesk Fusion

Enable rapid design exploration early on and uncover new possibilities in how you approach a given design problem in minutes using automated modeling.

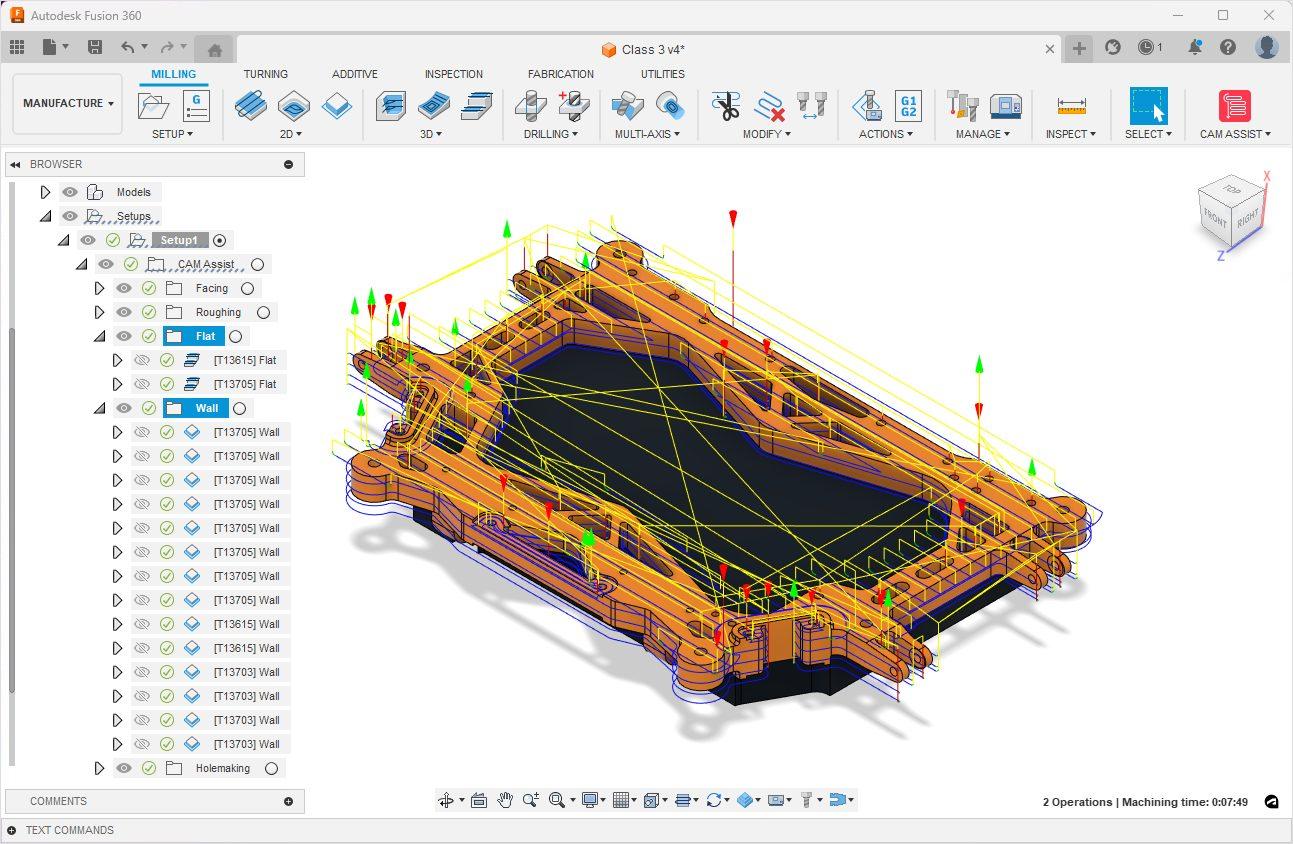

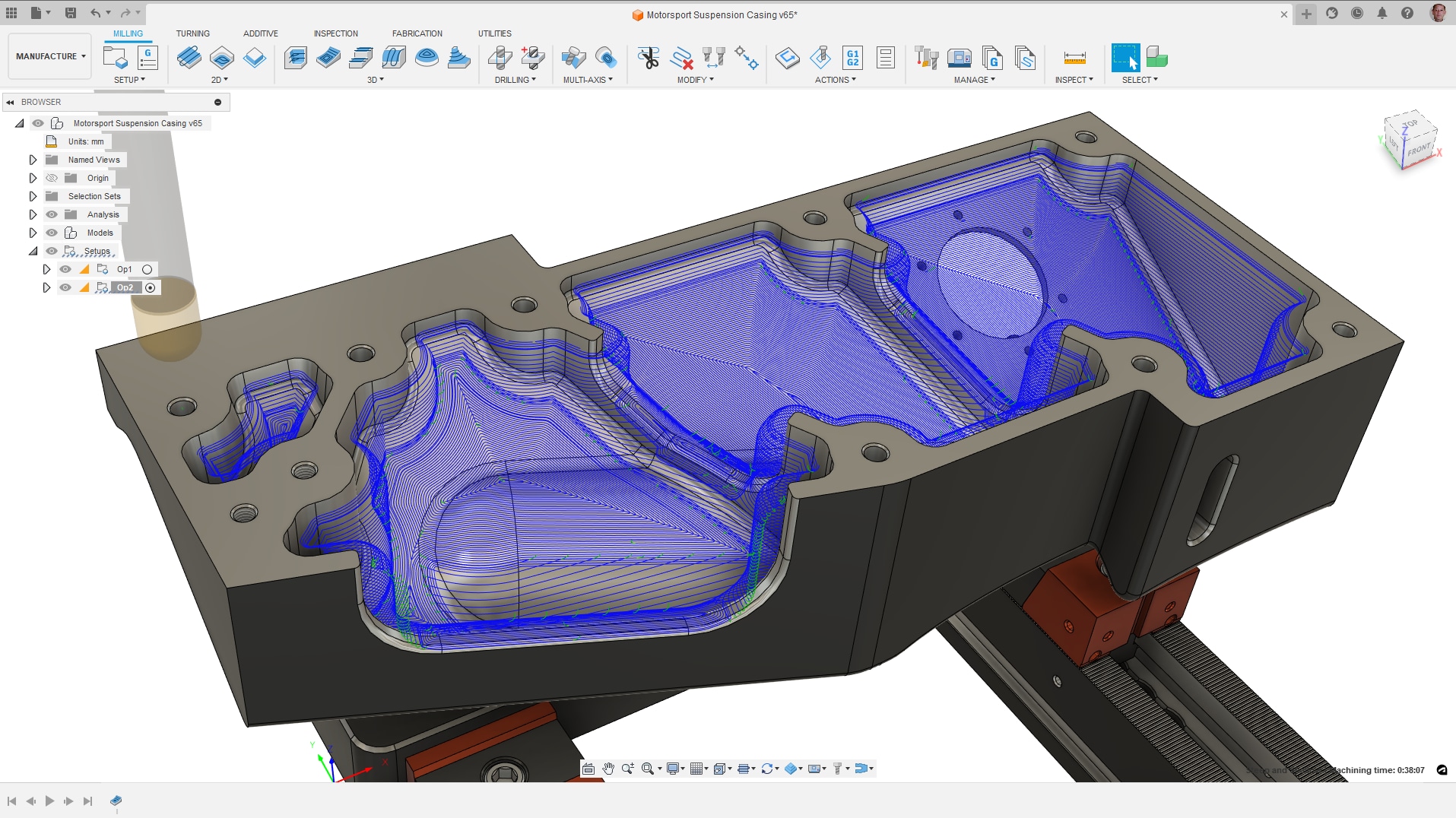

AutoDESK Fusion

Automate repetitive CAM programming tasks with strategies and estimations that might have once taken hours or days to develop, instantaneously with toolpath automation.

Autodesk Fusion

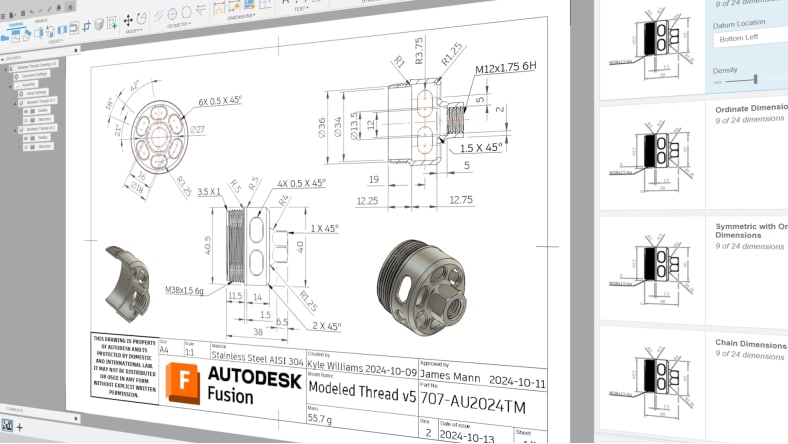

Streamline time-consuming tasks by leveraging AI-powered automation in Fusion for drawing standards, dimensioning, and sheet layout, enhancing design efficiency with automated drawings.

Autodesk Fusion

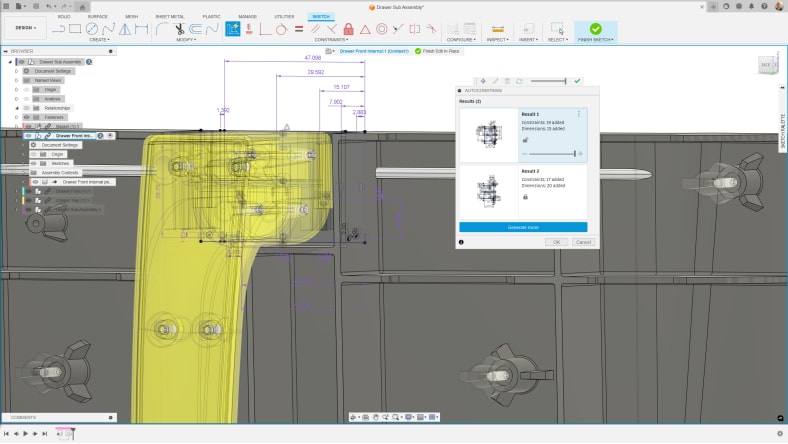

AI-powered AutoConstrain in Fusion automates the detection and application of critical dimensional constraints in design sketches, reducing time and errors.

Autodesk Fusion

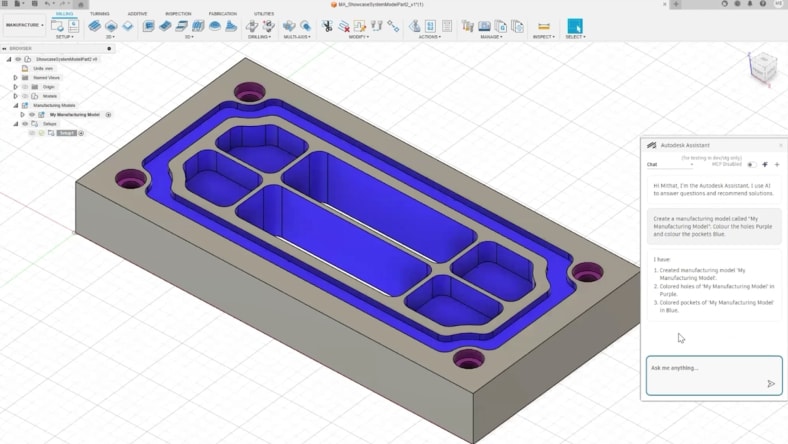

Autodesk Assistant provides contextual information and guidance in Fusion, delivering links to help, forums and other data sources to provide advice. This technology can even interact with projects and acts on the users' behalf.

Autodesk Fusion

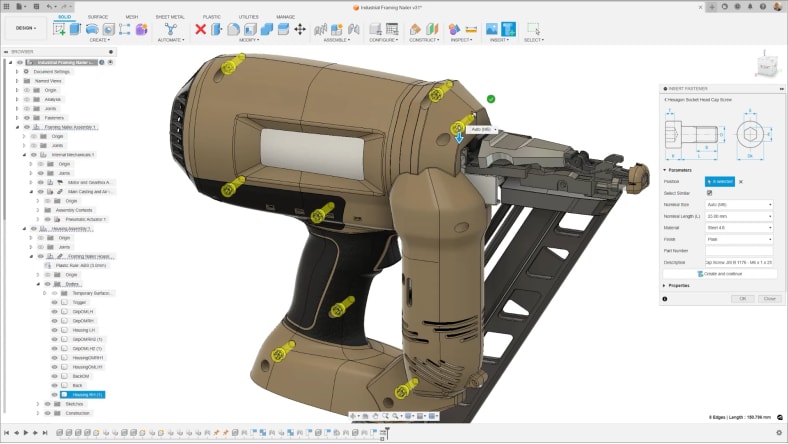

Fastener replacement tools use Autodesk AI to automatically detect and update fastener sizes across your design when requirements change. You can edit individual fasteners or entire groups in one step, ensuring all dimensions, joints, and Bill of Materials stay consistent and compliant.

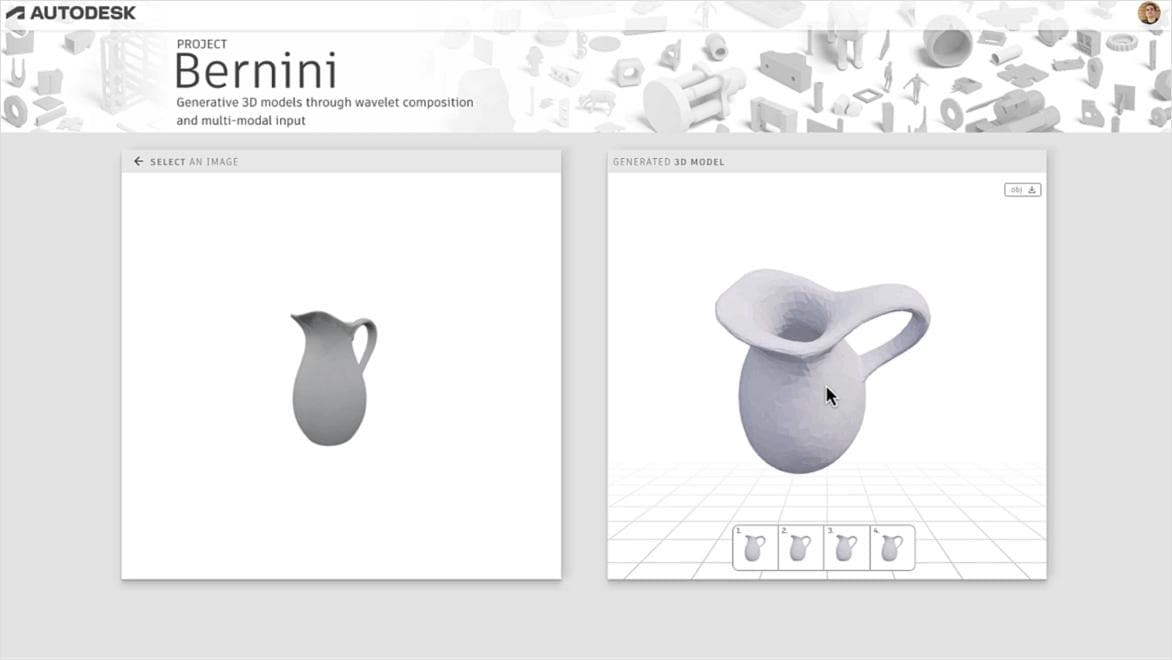

Autodesk ALIAS

Form Explorer accelerates 3D concept exploration with AI-driven design prompts. Use intelligent terminology and attribute definitions to generate and refine concepts, then convert them into subdivision models for precise geometry control.

The Autodesk Fusion industry cloud represents a new era of connected data and collaboration to design and make anything.

The Autodesk AI Lab is the world’s leading publisher of peer-reviewed original research on generative AI models trained for CAD geometry. Our global team of research scientists is dedicated to advancing both fundamental and applied artificial intelligence research.

Our global 2025 State of Design & Make research reflects a drop in overall sentiment, signifying that AI is following the classic tech hype cycle, as leaders face the reality of implementation, an ongoing technical skills shortage, and the limitations of the current technology. Despite these challenges, the majority of leaders say they will increase their investment in AI technology in the coming years.

Design & Make with Autodesk

The factory of the future is intuitive, smart, and loaded with sensors—all thanks to AI in manufacturing. Learn why it's important for future factories.

Fusion Blog

By partnering with industry leaders and integrating advanced AI-driven manufacturing solutions, Autodesk Fusion is transforming the way products are designed and manufactured.

Design & Make with Autodesk

At Kia Global Design, generative AI is helping automotive designers ideate and innovate faster, accelerating the process of taking a design from initial concept to final form.

Industrial design software to sketch, concept model, surface, and visualize. Available as Alias Concept, Surface, and AutoStudio.

AI can be used in product development, predictive maintenance, quality control, and more. It can also be used to create digital twins of physical entities for testing and improvement.

AI can improve speed, precision, and quality control in manufacturing. It can also lead to the creation of fully autonomous factories run by AI systems directing robotic production lines.

AI can be used for predictive maintenance, machine-generated events monitoring, and more. It can also help increase revenue, reduce conversion costs, and improve customer service and quality.

Yes, AI can identify and rectify possible product failures before they happen.

Autodesk AI-powered features in Autodesk Fusion include Drawing Automation, AutoConstrain and Generative Design.

Drawing Automation in Autodesk Fusion streamlines the creation of 2D manufacturing drawings by automatically generating views, dimensions, and annotations – saving time, reducing errors, and helping to improve design-to-production accuracy.

AutoConstrain in Autodesk Fusion enhances design efficiency by automatically applying relevant geometric constraints, helping ensure accuracy and reducing manual adjustments. This streamlines the sketching process, improves consistency, and accelerates design iterations.

Generative Design in Autodesk Fusion leverages AI-driven algorithms to explore optimized design solutions, reducing material usage, improving performance, and accelerating innovation—all while meeting engineering constraints and manufacturing requirements

Some Autodesk AI features do not leverage machine learning and so do not require data for training of the underlying models. When an AI feature does require data for training, Autodesk uses different data sources depending on the feature. You can learn more about whether an Autodesk AI feature relies on machine learning and what data sources are used for training on the feature’s AI transparency card, located within the Trusted AI section of Autodesk's Trust Center. Note: Additional transparency cards are coming soon.