& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Cabinet design software helps professional cabinetmakers and DIYers create detailed cabinetry layouts and plans. Cabinetmaking design software is a powerful tool for visualizing a project, ensuring more accurate measurements, and providing robust customization options.

For example, when working on kitchen cabinet design, a remodeler can use a cabinet design software program to visualize design concepts in both 2D and 3D formats. Whether the project is simple or complex, the ability to visualize how the designs will look in the space boosts accuracy and reduces the risk of costly mistakes. And because the software is cloud-based, cabinetmakers experience greater flexibility and can collaborate with stakeholders more effectively.

Cabinets serve as focal points in any kitchen, defining the overall look and feel of the space while also providing functionality for storage. Base cabinets sit below the countertop and usually measure two feet deep and 34.5 inches in height; meanwhile, wall cabinets tend to be 12 to 24 inches deep and are attached to the wall above the counter area.

Custom cabinets come in all shapes and sizes, depending on the space and needs. In a typical kitchen remodel, for example, a homeowner might employ a mix of standard base and wall cabinets and then turn to a custom cabinetmaker to maximize storage space.

One thing to consider in cabinet design is framed vs. frameless. The doors of framed cabinets are attached to an external frame affixed to the cabinet. With frameless cabinets, the doors are attached directly to the cabinet. This choice affects how and where the doors are attached, the amount of storage space available, and durability.

Finally, cabinet designers must consider building materials, which affect durability and quality. For instance, a cabinet constructed of particleboard will break down faster than one made from stainless steel or solid wood. When choosing materials, designers consider factors like heat and moisture resistance, cost, and availability.

Stock cabinets come in predetermined sizes, paint and stain colors, and hardware—key reasons why they’re the most affordable option. However, they won’t always work in a kitchen or bathroom space, which is why semi-custom cabinets are offered. These cabinets cost a little more but provide more flexibility in sizes, aesthetics, and hardware. Custom cabinets are, by definition, highly customizable.

A kitchen remodel might use a mix of stock base cabinets to support a countertop, some semi-custom ones for the wall, and custom cabinets for corners or areas where only a bespoke design will work. That latter category—specialty cabinets—can add unique functionality and style.

Cabinet designers have a host of materials to choose from. Here are a few commonly used ones and their advantages and drawbacks.

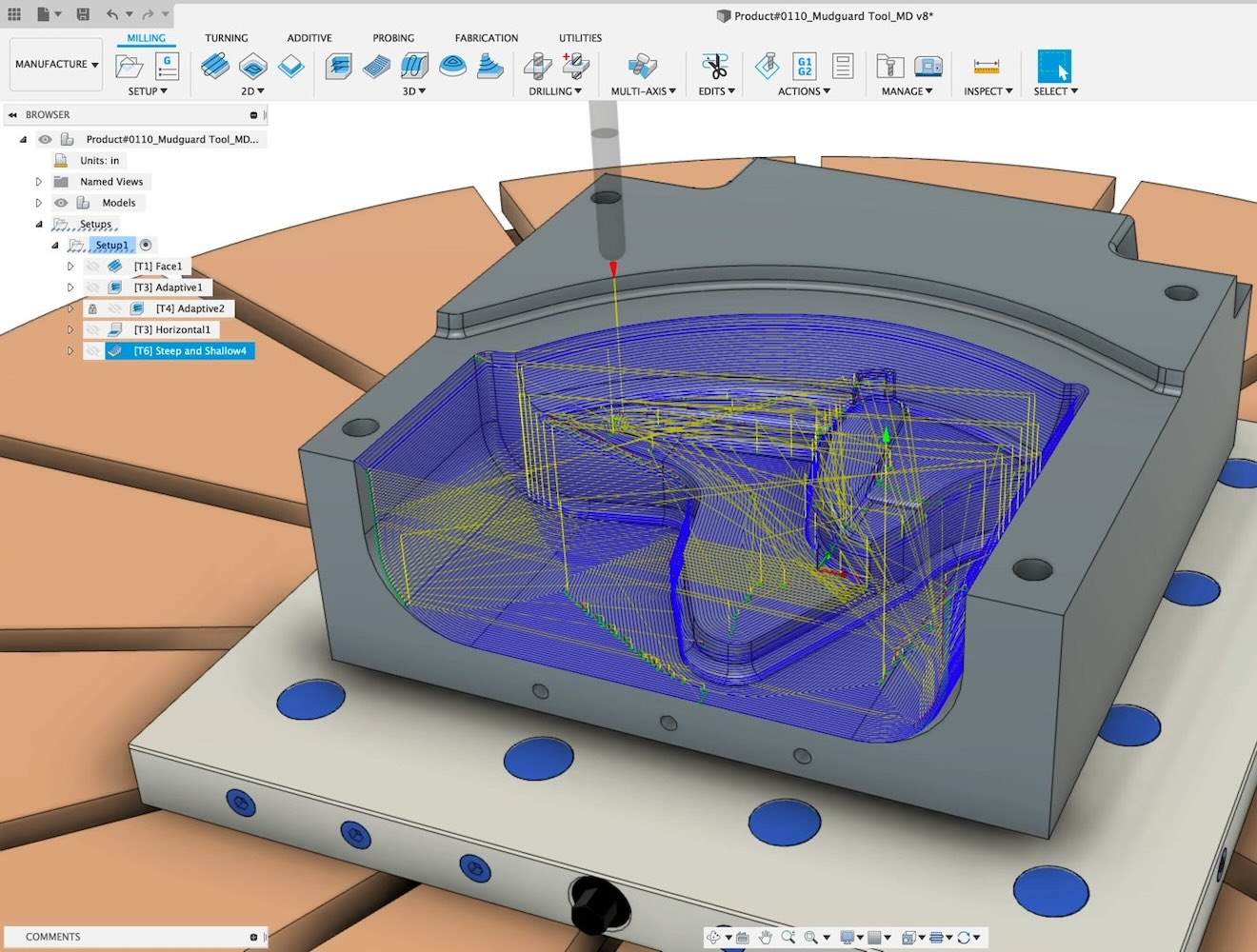

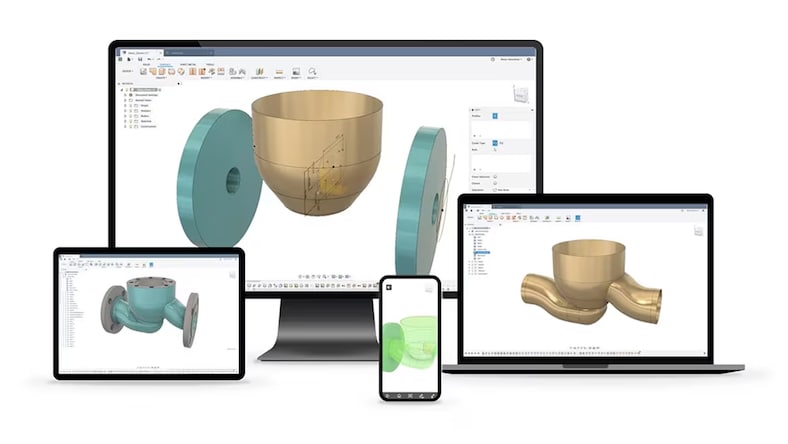

Autodesk Fusion is a highly flexible tool for 3D cabinet design, woodworking, and furniture design. It integrates CAD, CAM, and CAE, which speeds up the design and manufacturing process, allowing users to manage all design aspects within a single product development solution. Fusion also features automated machining and multi-sheet nesting, ensuring that when production begins, cuts will be more precise.

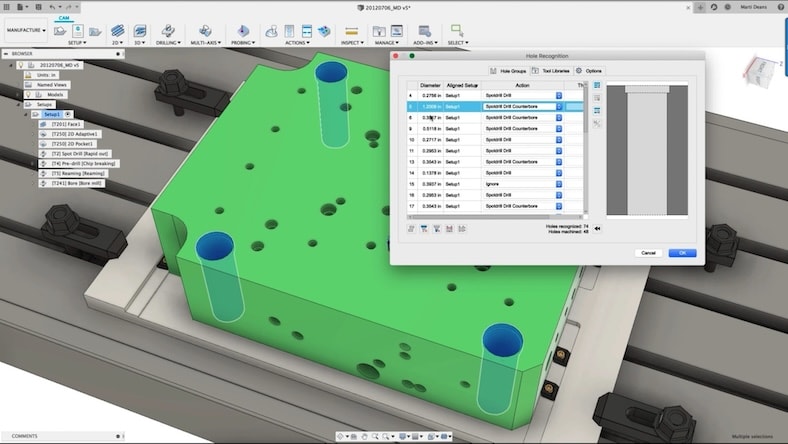

Fusion supports milling and laser cutting, enabling intricate designs limited only by your imagination. Designed for enhanced precision, Fusion boasts features such as automatic hole recognition and collision avoidance.

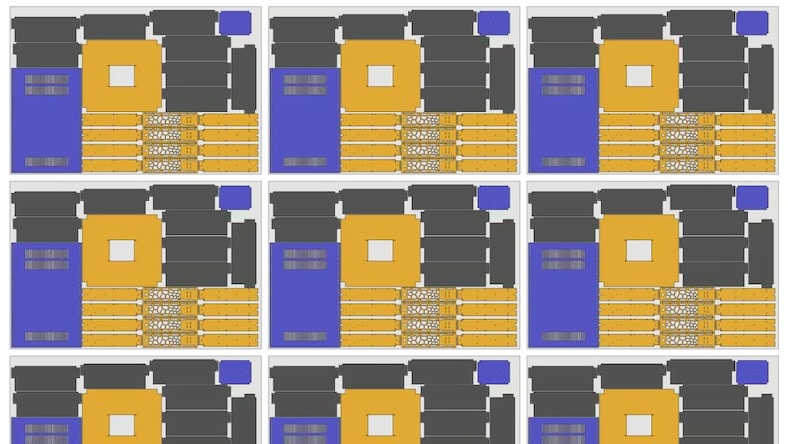

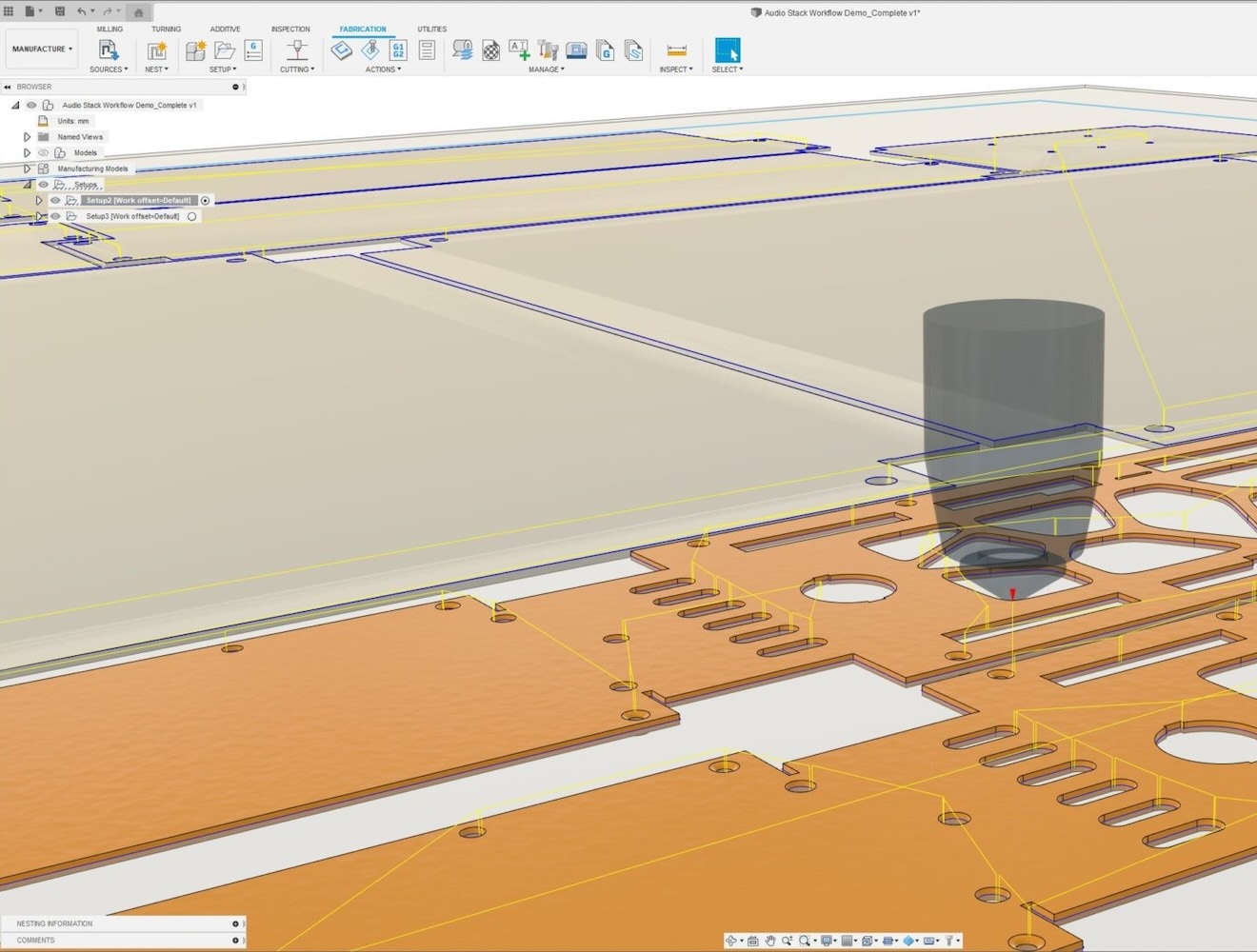

In cabinet production, nesting ensures that as much of the material gets used as possible, reducing waste and saving money. Fusion’s native algorithms help designers achieve the most efficient layouts before cutting begins, which means enhanced profit margins.

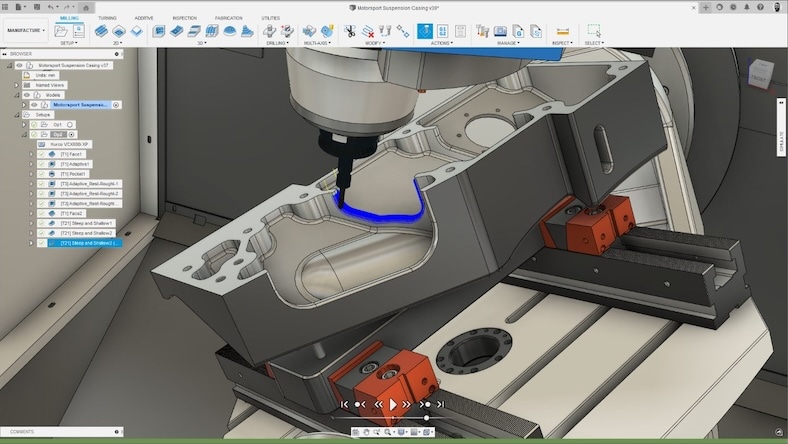

Complex shapes are common in advanced cabinet design projects that require makers to use 4- and 5-axis machining. Fusion provides advanced CAM functionality, enabling intricate designs with fewer setups, enhancing efficiency, and reducing production time.

If you’re a DIY remodeler, hiring a professional to design and build custom cabinets can be expensive. With Fusion, you can create custom cabinets tailored to your home with high-quality materials, which will help keep your budget in check. The unique designs you create may boost your home’s value—helping recoup the remodeling costs—and improve your day-to-day life. Meanwhile, readily available cabinets can cost anywhere from $4,000 to $13,000 to replace, depending on the size of the kitchen. Designing and building your own might end up being a cost-effective choice.

3D cabinet design software greatly improves efficiency and accuracy during the design process, which means fewer issues during manufacturing.

Work faster and smarter, collaborate easier, and manufacture kitchen cabinet parts with far fewer errors.

Quickly customize your designs and make adjustments using Fusion’s easy-to-learn interface.

When it’s time to fire up a CNC machine, Fusion produces machine-ready G-code so you can produce components without a hitch.

Professional-grade product design and engineering tools for 3D mechanical design, simulation, visualization, and documentation.

2D and 3D CAD tools, with enhanced insights, AI-automations, and collaboration features. Subscription includes AutoCAD on desktop, web, mobile, and seven specialized toolsets.

Best-in-class tool for 2D CAD drafting, drawing, and documentation. Subscription includes AutoCAD LT on desktop, web, and mobile.

Get Inventor + AutoCAD + Autodesk Fusion + more—Professional-grade tools for product development and manufacturing planning.

Fusion helps streamline the transition from 2D to 3D design and updates automatically whenever a design changes. Fusion also includes milling, turning, and automated machining features for error-free production, as well as multi-sheet nesting and multi-axis machining.

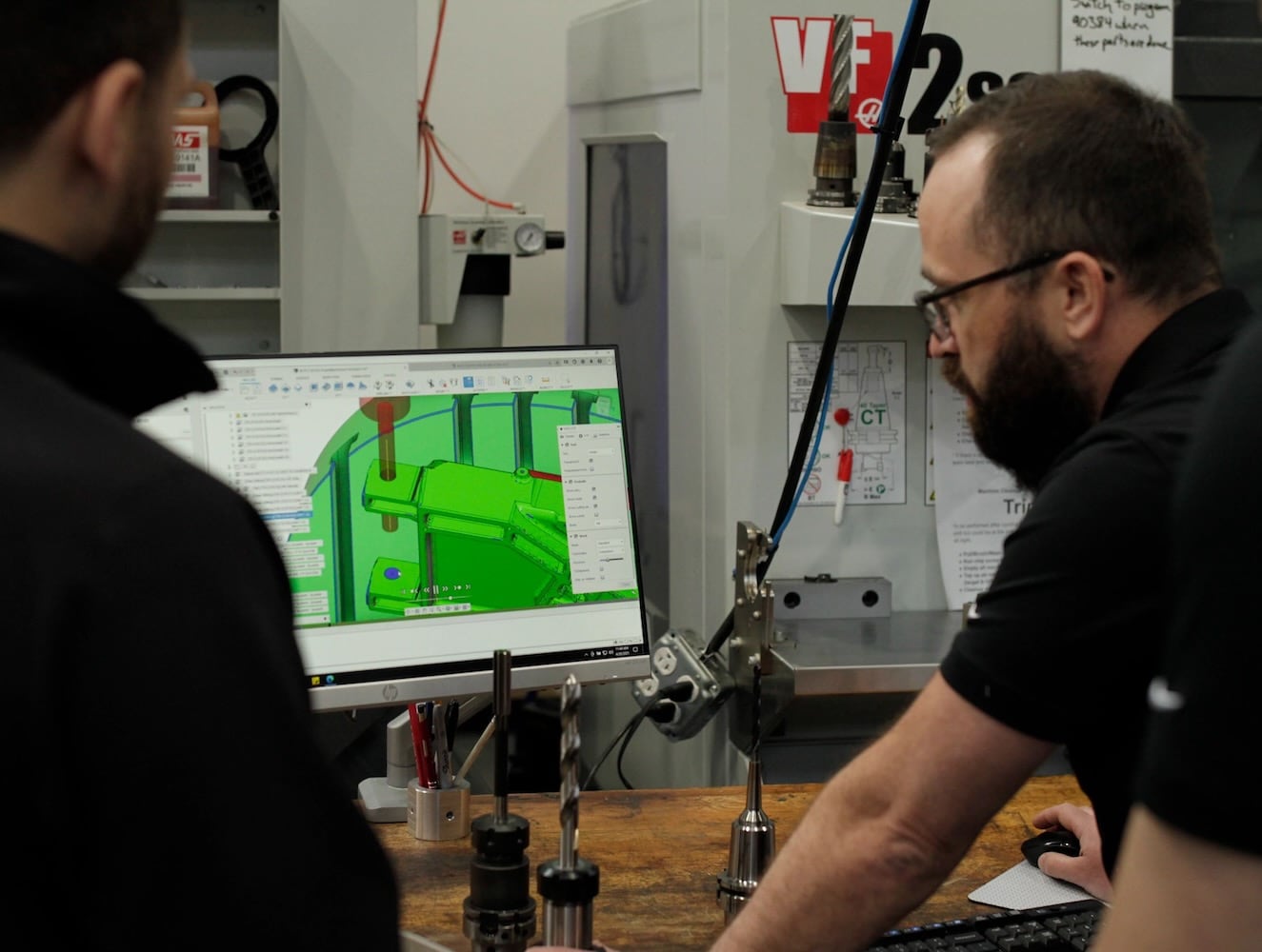

Image courtesy of Conturo Prototyping.

Cabinet designers can take advantage of Fusion’s advanced automated machining capabilities and parametric modeling features to generate creative layouts. It empowers innovative cabinet solutions while enhancing functionality and aesthetics.

Intelligent algorithms enhance material efficiency, reduce errors during production, optimize material use, minimize waste, and increase profit margins with effective cut patterns.

Fusion provides great flexibility for cabinet designers by supporting various CAM processes; in addition, offline programming prevents production slowdowns. With Fusion, production flows smoothly, no matter how complex the design.

Cabinetmaking design software offers distinct advantages for cabinetmakers. By integrating design and manufacturing data, it spurs swift decision making, enhancing efficiency and productivity. In addition, automated toolpath creation for CNC machines makes production much easier and less prone to error.

In kitchen cabinet design, precision and efficiency are crucial to a good end product. With Fusion, automated CNC programming ensures components are rendered more precisely, reducing scrap rates and helping designers make the most out of expensive materials. It also integrates advanced tools, boosting workflow efficiency.

Fusion makes it easy for cabinet designers to elicit real-time feedback from stakeholders via cloud-based collaboration tools. Built to enhance teamwork between design and production teams, Fusion creates a smooth, efficient process from start to finish. And if a roadblock impedes progress, Autodesk’s robust community of experts is ready to help.

When designing cabinets, customization is key. Fusion gives designers great flexibility, enhancing creativity and keeping clients satisfied. No matter what your client needs, Fusion will ensure that the project will meet their requirements.

Yes, cabinet design software isn’t just for new construction. Whether you’re a professional remodeler or a DIY homeowner, you can use the software to design cabinets that will fit your space perfectly.

Yes, Fusion offers a free version for designers who generate less than $1,000 in revenue per year. This version comes with advanced design tools, a user-friendly interface, and comprehensive online support to help master the software quickly.

Fusion features a user-friendly interface and was created to help streamline design and manufacturing processes.

Yes. Fusion produces machine-ready G-code, which enhances machining efficiency through fewer manual adjustments.

Inventor offers advanced 3D modeling capabilities and more precise engineering features so cabinet designers can create high-quality construction and innovative designs.

AutoCAD enhances cabinet design by providing more precise 2D layouts, essential for drafting detailed plans and ensuring they are more accurate when produced. The Analyzer CAD app is also a helpful tool for saving time when designing custom cabinets.

Fusion users don’t have to go it alone—they can get up to speed quickly via tutorials, webinars, and community forums. Autodesk also offers direct support services.

Some top design styles for cabinet doors include raised panel doors, which offer a traditional, elegant look; minimalist flat panel doors for the modern touch; full overlay doors to create a seamless appearance; and partial overlay doors for a traditional look.