& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

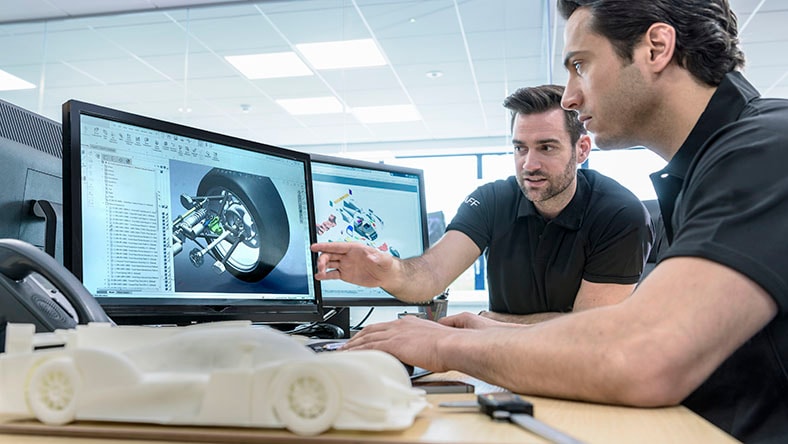

Professional CAD/CAM tools built on Inventor and AutoCAD

Mass customization is a manufacturing approach that allows customers to personalize products while the business retains some of the speed and lower costs of mass production. Mass customization uses advanced manufacturing technologies to customize products efficiently—and has the marketing benefit of making customers happy and strengthening brand loyalty.

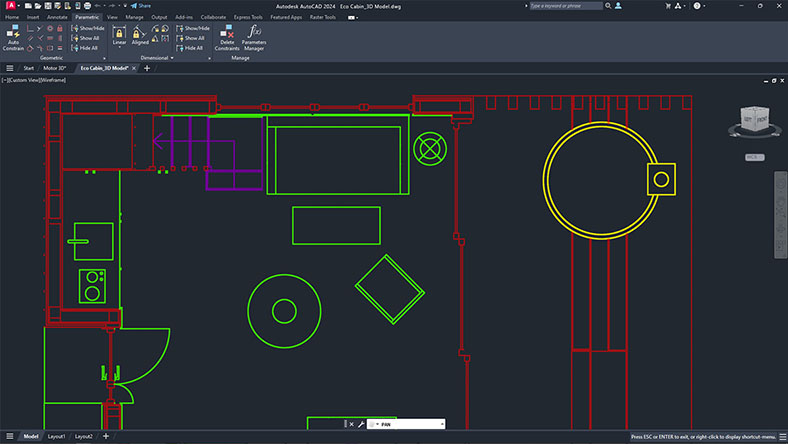

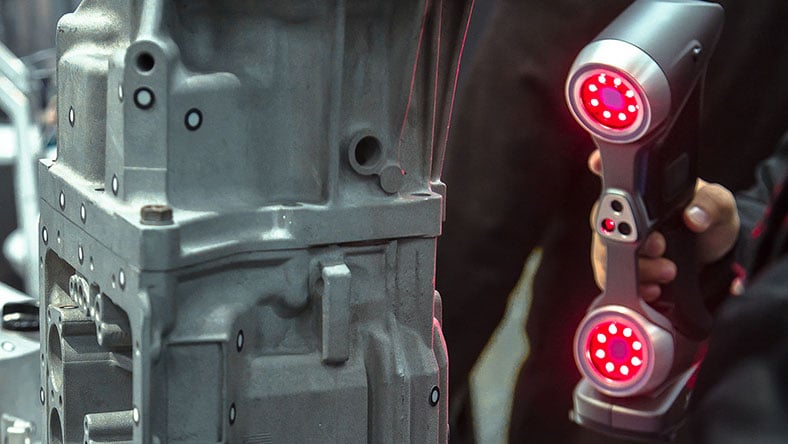

Mass customization affects every stage of the product lifecycle. It begins before design, at the brainstorming stage, where businesses can decide how to customize a product. Next, in the 3D modeling stage, designers can create custom-fit models based on 3D scans or customizable designs in CAD; using Autodesk Fusion’s configuration features, designers can include many configuration options within a single CAD file.

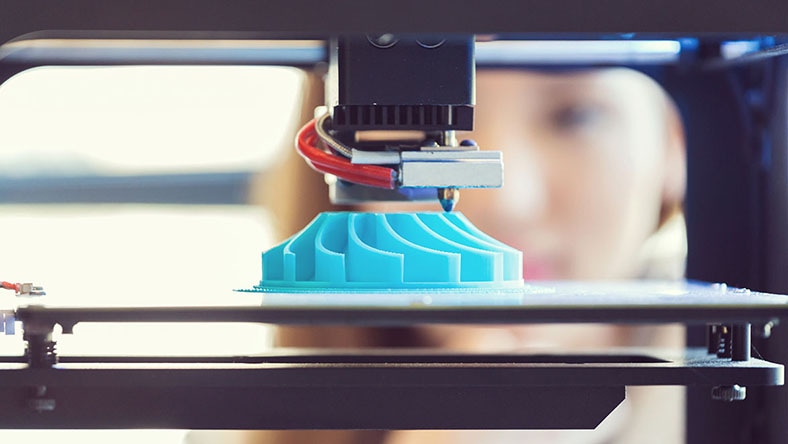

In the next manufacturing stage, mass customization products are often made with methods that require no tooling (such as 3D printers), CNC machines, and other approaches that can accommodate rapid tooling. Autodesk Fusion is the rare mass-customization software that combines both CAD and CAM (computer-aided manufacturing) abilities. It also integrates with many 3D printers and CNC machines, to easily go from designing to making your product.

If the final product combines the customized parts with a standardized sub-assembly, there could be an additional assembly stage. Here, businesses can stay efficient and cost-effective by using off-the-shelf components and automation to make the standard portions of the product.

Mass customization even affects post-production stages including sales and distribution. Many sellers use online or app-based product configurators, which let customers choose functions or design elements for their purchase. Finally, direct-to-consumer distribution sends out the personalized product to the buyer, who then reaps the benefits of mass customization.

Many consumers today don’t want the same old product everyone else has—a generic solution to an individualized problem. They would prefer a product tailor-made for them. Deloitte research revealed that for some product categories, more than half of potential customers were interested in buying customized products and many would pay more or wait longer to obtain them. The ability to deliver such mass personalization provides a significant competitive advantage, and Autodesk’s mass customization software can help give manufacturers that edge.

To be economically practical, the mass customization process must take advantage of emerging technological innovations to design, manufacture, and assemble products and collect data at every stage of the process. Mass customization manufacturers prefer machines that fabricate without extra tooling or that use low-cost rapid tooling.

Like most modern product design, the mass customization process starts with CAD modeling. In addition to the flexibility and speed of standard 3D modeling, certain CAD software offers a range of specific tools for mass customization. These may include industry-specific tools for making custom implants or prosthetics for the medical sector, for example, or for making customized jewelry. Configurations in Autodesk Fusion make it a mass-customization software where designers can quickly create multiple versions of a product from a single CAD file.

CAD mass customization software also gets a hand from 3D scanning technology. Using dedicated 3D scanners or smartphone cameras equipped with LiDAR or photogrammetry apps, 3D scanning analyzes physical objects and turns their dimensions into 3D models that can be edited for manufacturing. For the process of mass customization, 3D scanning can scan people’s bodies in order to design custom-fit clothes or wearable devices, faces for custom-fit glasses, and even ear canals or teeth for custom-fit earphones, dental retainers, and more.

Fabrication for mass customization often uses 3D printing—because 3D printing requires no tooling, changing the CAD file is all it takes to make design tweaks or switch to a different product. With 3D printing, complex shapes can be created that would otherwise be difficult to achieve by other means. However, when mass customization calls for using other machines, it benefits from rapid tooling or traditional manufacturing methods such as injection molding. Rapid tooling often takes advantage of novel or limited-run parts that would be too expensive to make with standard tooling, and the tools are often produced with 3D printing.

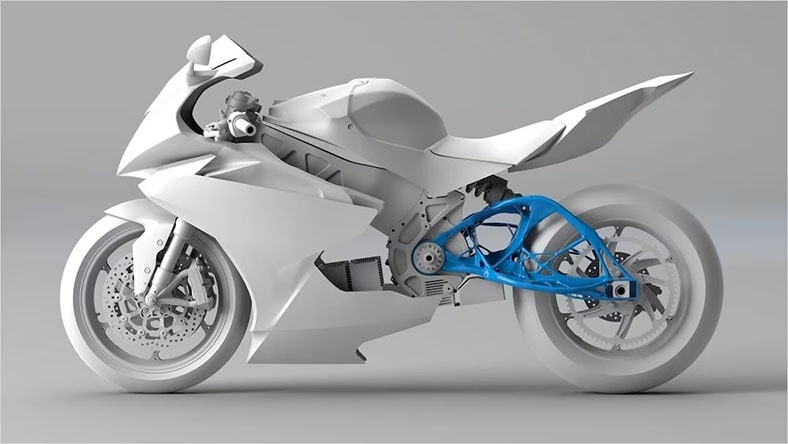

The rapid iterations of generative design also play a part in mass customization because the process can output thousands of design options that adhere to specific input parameters in minutes. Generative design uses algorithms—sometimes incorporating artificial intelligence (AI)—and high-powered computation to run simulations and churn out optimal design options that designers can choose from and refine. These geometrically unique designs are often best produced using additive manufacturing with 3D printers, subtractive manufacturing using CNC machines, or some combination.

With mass customization and mass personalization jobs, many distinct parts are involved; sometimes, every product made contains one or more unique parts. That makes job- and part-tracking more difficult. However, automation and robotics work together and connect everything through the sensor data of the Industrial Internet of Things (IIoT) to centralize information on cloud data platforms for smoother operation. Robotics are also becoming more accessible to program and safer to interact with through technologies like computer vision. These factors benefit the highly flexible production methods needed for mass customization manufacturing.

With collaborative customization, the manufacturer co-creates the product with the customer, who controls the design’s customization. A good collaborative mass customization example is the Nike by You online platform, where customers use a product configurator to modify shoe designs that are produced and shipped to them.

Adaptive customization describes products that are produced in a standard way but have customizable uses once they are in the customer’s hands. For instance, smart home devices are everyday products. Once installed, the user can set them up and combine them with other devices to perform highly customizable automated tasks.

Transparent customization happens without the customer necessarily knowing about it and is often known as mass personalization. Typically, it’s based on customer preferences, behavior, and other data. For example, digital products and services often use machine-learning algorithms to customize social media feeds, media recommendations, or ads served based on a person’s user data. Transparent customization/mass personalization can even apply to physical products, like when L’Oreal used customer behavior and preference data from its app to tailor skin-care products, packaging, and quantities to customers’ needs.

The product doesn’t change for cosmetic customization, but the packaging or the way it’s presented changes to appeal to different individuals or groups of customers. Coca-Cola’s Share a Coke campaign was a famous cosmetic example of mass customization, which replaced the brand’s iconic logo with hundreds of regionally common names distributed to more than 80 countries.

Companies in many industries have embraced the benefits of mass customization. Some significant examples of mass customization include:

For purchasers of furniture products looking to personalize their homes, it’s a major plus to have the option to choose their own fabric and material finishes.

Many car companies have adopted a mass customization approach that includes a virtually limitless palette of custom colors, as well as dozens of options for interior features and optional extras.

Apparel customization options such as materials, sizes, patterns, and more allow customers to personalize their style, and clothing companies to expand their appeal.

Some eyeglass manufacturers provide options for customers to create their own combination of frames, lenses, and other design features.

Businesses that want to maximize value and help streamline inventory, waste, and overhead can use mass customization in conjunction with just-in-time (JIT) manufacturing. With JIT manufacturing, products are created to meet demand rather than being held in stock, which suits a mass personalization system where customers design elements of their product in advance. Autodesk’s just-in-time scheduling software can be of use here, allowing companies to manage inventory levels in real time.

Across industries, mass customization tangibly benefits every stage of the product development lifecycle, including:

With mass customization in Autodesk Fusion, designers and engineers can create multiple product variants in a single software model without multiplying design and manufacturing complexity. Product development and time-to-market accelerate quickly when it’s not necessary to painstakingly create and update design files for every configuration.

The right mass customization software gives designers the flexibility to explore and experiment with many features, materials, surfaces, and so on by setting up rule-based design automation and multiple product configurations within a single model.

Autodesk’s mass customization software lets designers run simulations and testing on all product variants before moving to prototyping and production. When it’s time to make the physical product, they can update CAM setups for every variant with a single click.

Powerful product design and engineering tools for 3D mechanical design, simulation, visualization, and documentation.

2D and 3D CAD tools, with enhanced insights, AI-automations, and collaboration features. Subscription includes AutoCAD on desktop, web, mobile, and seven specialized toolsets.

TOUSEK

Though based in Austria, this automatic gate company complies with differing regulations and standards across over 60 national borders. It uses Autodesk Fusion to customize designs while merging electronics with mechanics.

Image courtesy of Tousek

PEMBREE

PEMBREE makes carbon-neutral and 99.9% recyclable bicycle pedals. But bicycles rarely follow sizing standards: To make many different-sized pedals for many bikes, the company saves time using the mass customization features of Autodesk Fusion, where making a single adjustment can apply to many design variations.

Image courtesy of PEMBREE Ltd

UNIK METAL

This fabrication studio for architectural and interior design projects uses configurations in Autodesk Fusion to adapt staircases, guardrails, glass walls, and other components to any dimensional differences within a space without creating and editing separate design files.

BBI AUTOSPORT

BBi Autosport helped modify a Porsche into the Hoonipigasus to race the notorious Pikes Peak International Hill Climb. The shop designed, customized, and built many parts for this job using Autodesk Fusion's integrated CAD/CAM design and make abilities.

While there are many benefits of mass customization, it’s also more complex than simply manufacturing a one-size-fits-all product. For one thing, mass customization requires sophisticated planning to maintain supply levels of all necessary components. Mass customization’s short-term financial costs can be higher as well. However, once the system is set up with the necessary mass customization manufacturing tools and software in place, the payoff from increased sales and customer satisfaction can be far greater than with generic production.

Learn the interface and get instructions for creating design variations using a single parametric model in Autodesk Fusion’s configurations with this help file and tutorial video.

Configurations in Autodesk Fusion let users create and manage many design variations from a single unified model and help streamline mass customization manufacturing workflows by quickly shifting materials, production runs, and more.

Peruse the possibilities for creating design variations and accelerating time to market with configurations in Autodesk Fusion and learn how to access them in this helpful overview.

Learn how to use iLogic forms to automate the configuration of assemblies in Autodesk Inventor.

In this video tutorial (4:37 min.), learn how to automate design processes and configure your products in Inventor’s iLogic.

Download this white paper to learn about the Housing Agency System proposal, which uses building information modeling (BIM) in architectural parametric modeling software to mass-customize housing to individual resident needs and local climate conditions.

One mass customization example is the Hasbro Selfie Series, a product campaign that personalized action figures with customers’ likenesses. Users scanned their faces into Hasbro’s app, then picked hairstyles and other configurations. The toys were assembled with standardized action-figure bodies to go with the customized, user-based heads.

In another example of mass customization, Gilette’s Razor Maker campaign offered several razor handle designs and colors on an online product configurator. The custom razor handles were 3D printed and assembled with standard razors for direct-to-consumer shipping.

The advantages and disadvantages of mass customization are as follows:

Traditionally, the difference between mass customization and mass personalization has been whether the process tailors a unique product for a person. With mass customization, customers typically use some product configurator to select options such as colors, finishes, materials, and more—options that don’t create unique product geometry for a single person.

By contrast, mass personalization modifies a product in a completely individualized way. The proliferation of 3D printing has made it possible to deliver unique product geometries to individuals at a larger scale, blurring the lines between mass customization and mass personalization.

The characteristics of mass customization are a high level of customization combined with the capacity for high production volume through advanced manufacturing technologies such as 3D scanning, 3D printing, automation, and rapid tooling. The costs per part are relatively affordable, and manufacturing those parts is much faster than custom manufacturing.