& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

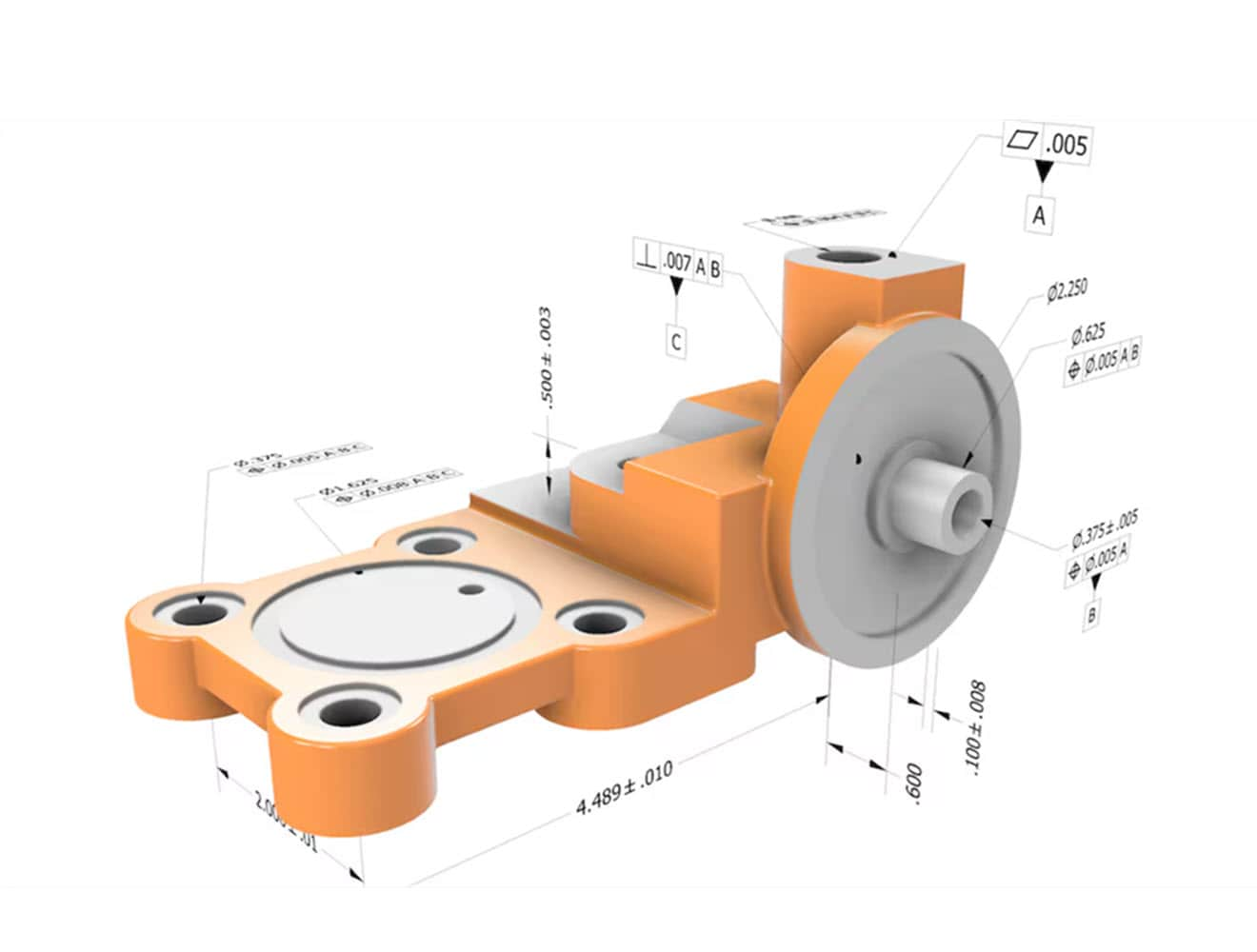

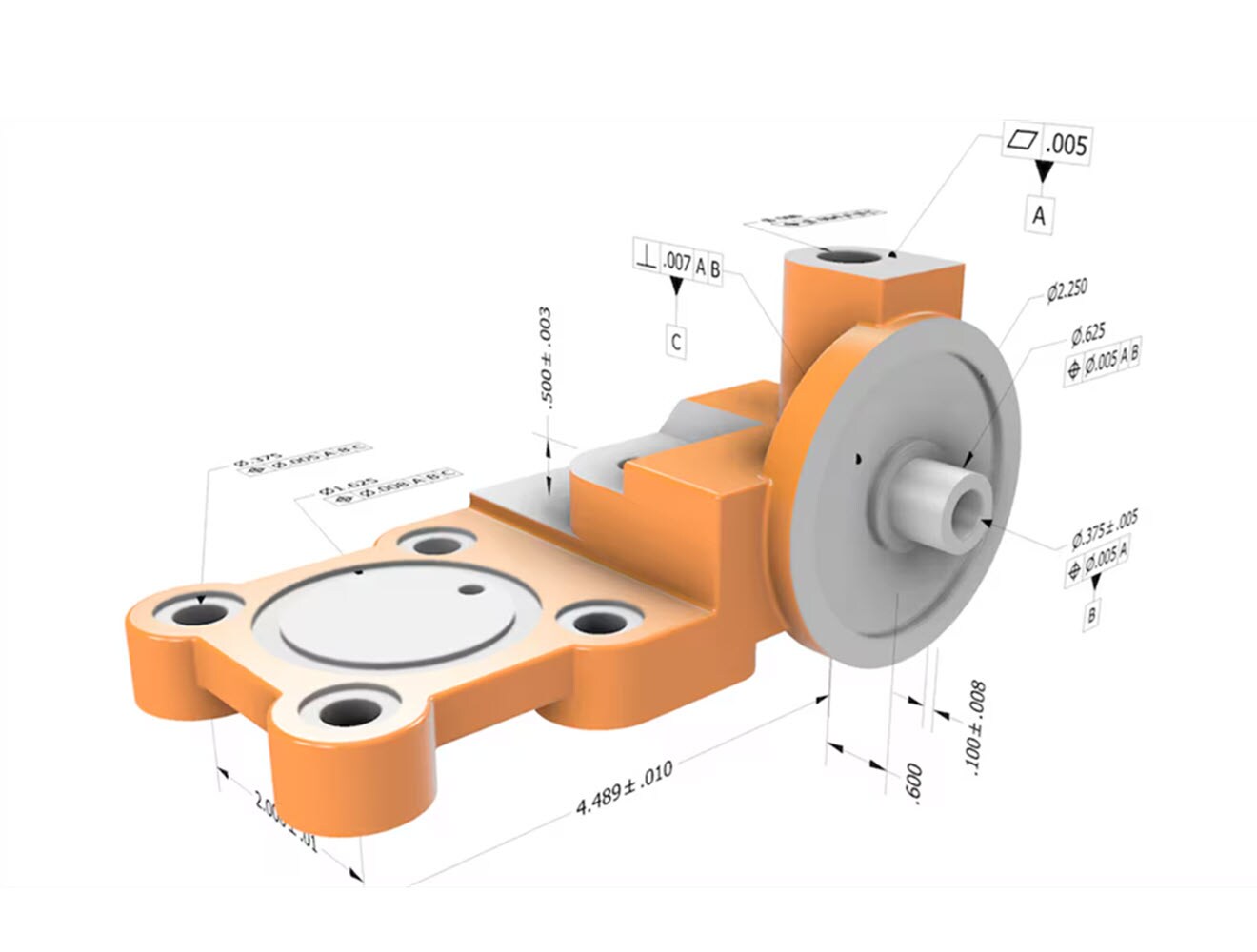

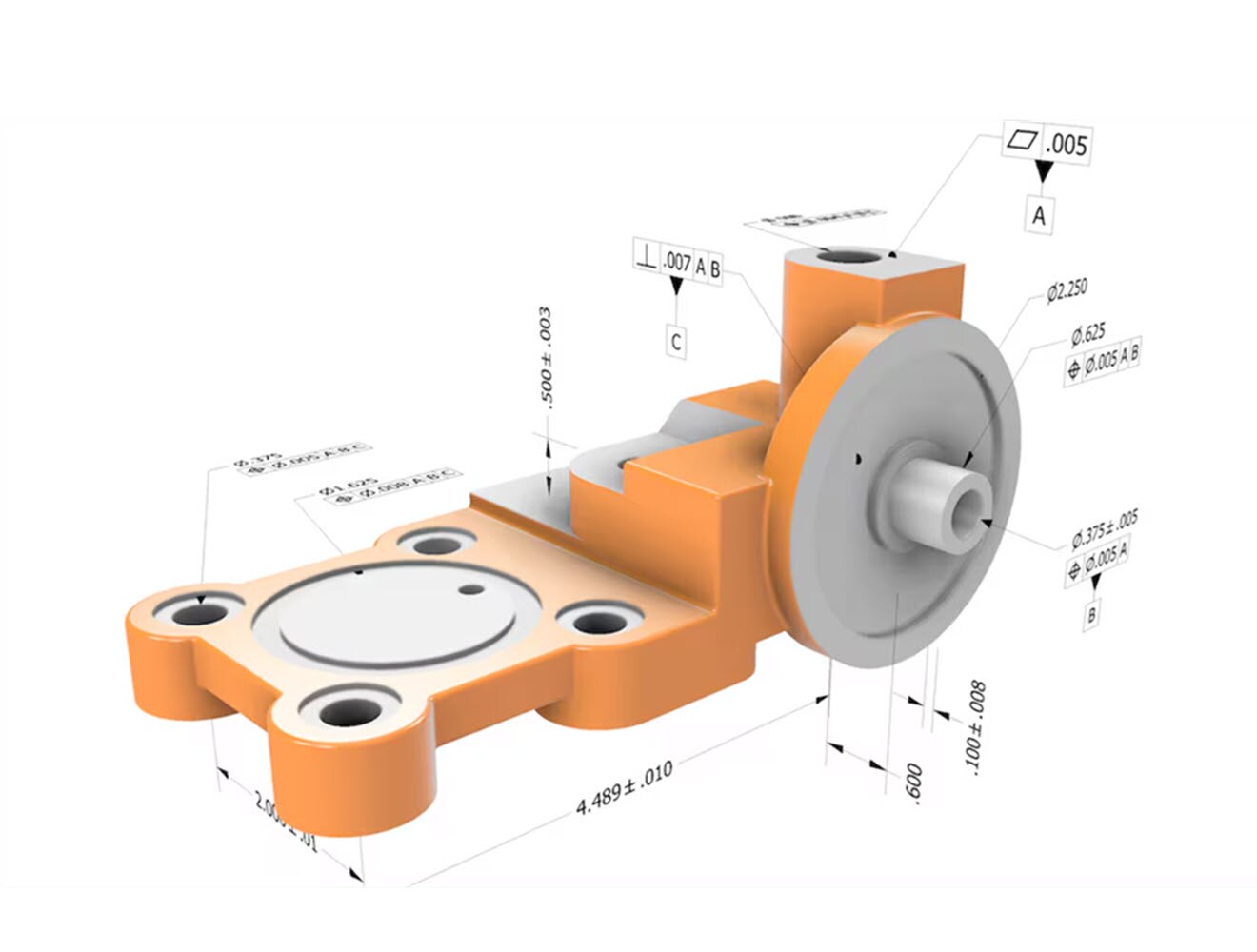

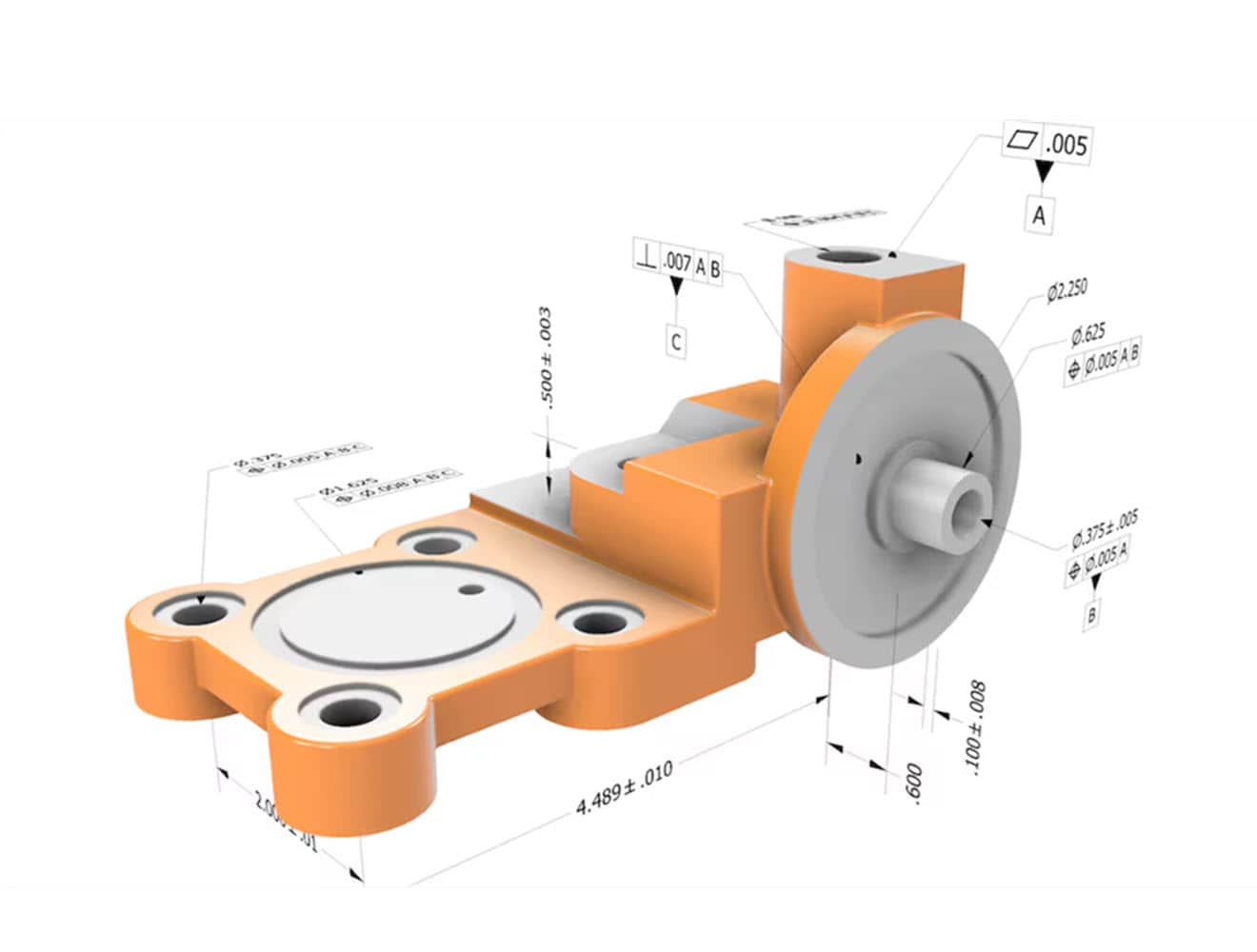

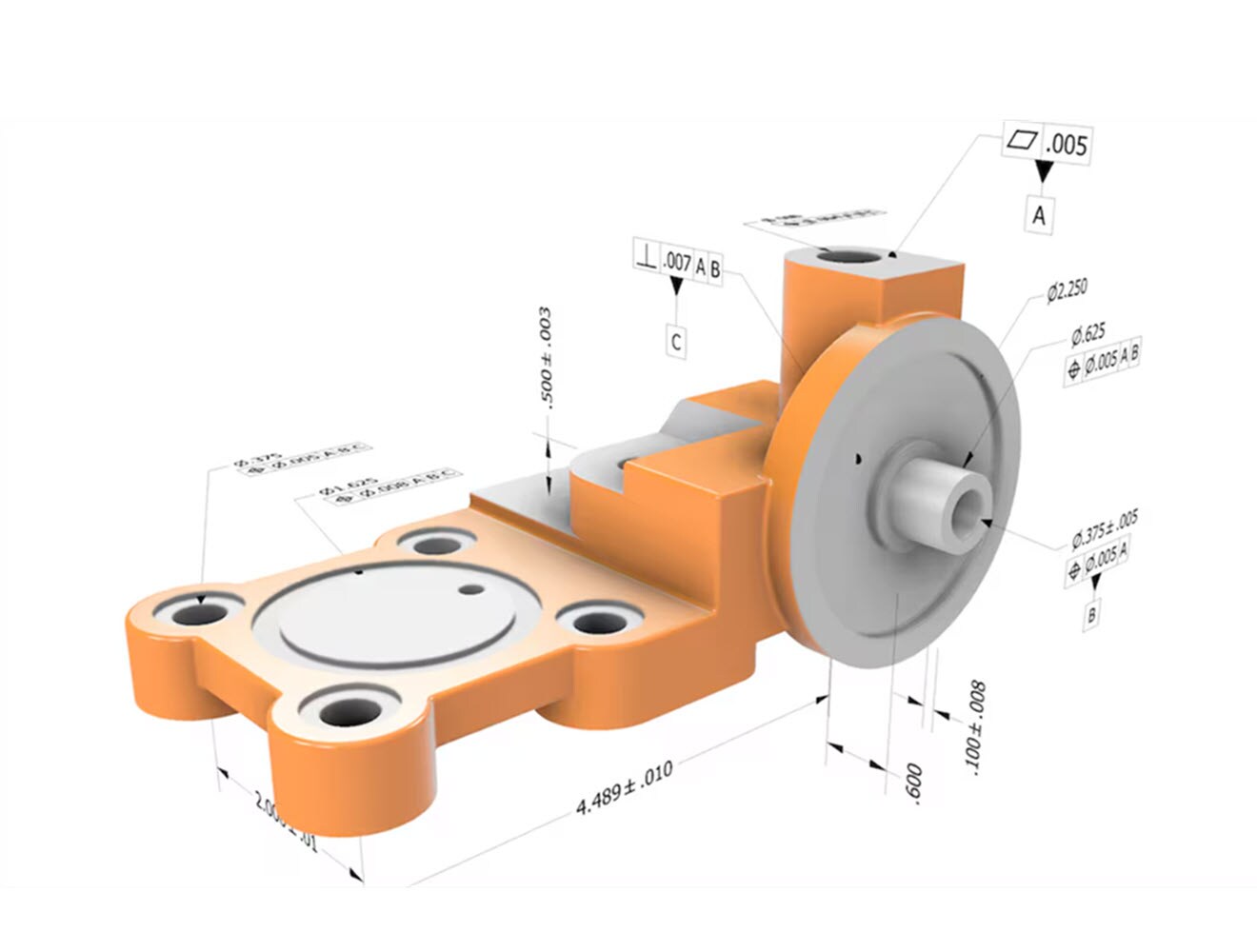

Model-based definition (MBD) is a technical approach to product design and manufacturing where the digital 3D model serves as the primary source of information. Instead of relying on traditional 2D drawings, MBD integrates all the necessary data directly into the 3D model, including geometric dimensions, tolerances, material specifications, and other engineering details.

Overall, model-based definition is an important component of digital transformation in design and manufacturing, driving greater efficiency, accuracy, and collaboration.

Designers and manufacturers face constant pressure to work faster but often resist it because they equate working faster with reduced quality when working on complex products and assemblies. Here's why product developers find MBD important:

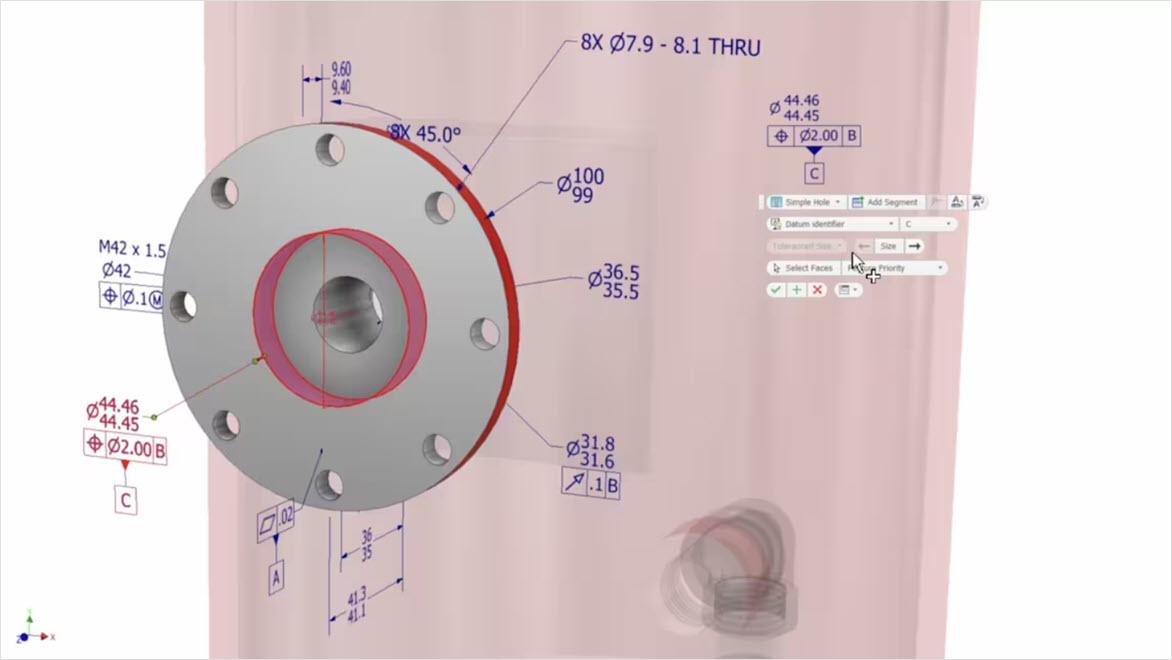

Implementing model-based definition (MBD) seamlessly replaces 2D drawings with 3D CAD models that contain all essential product information. This shortens the development cycle by removing the need for technical drawings and provides accurate product manufacturing information (PMI) to stakeholders.

This information includes geometric dimensioning and tolerancing (GD&T) symbols and data, materials, standard dimensions, configurations, design intent, and quality requirements. It also includes the bill of materials and other manufacturing notes, such as surface finishing details.

Product data management (PDM) software digitally manages the 3D CAD model and its revisions. This secures data and makes sure that all stakeholders have access to the right information at the right time.

Although the traditional method of conveying requirements and design intent through 2D drawings is well established, it's not without flaws. Producing and interpreting 2D graphics requires significant time, skill, and training. 2D drawings can also be prone to misinterpretation, leading to production delays, scraps, and costly rework.

Due to the need for tight tolerances in industries like aerospace, MBD was standardized in the 2003 ASME Y14.41 "Digital Product Definition Data Practices" by industry leaders such as Boeing, Caterpillar, and Rolls-Royce. This standardization aids in global collaboration among companies and teams across different countries and languages.

A 2016 NIST study found that using MBD can reduce the design-to-manufacturing-to-inspection process by about 75% compared to 2D paper drawings. MBD practices have also contributed to the emergence of "model-based enterprises" (MBE), which optimize efficiencies from 3D model data across internal teams, external suppliers, and partners.

Powerful product design and engineering tools for 3D mechanical design, simulation, visualization, and documentation.

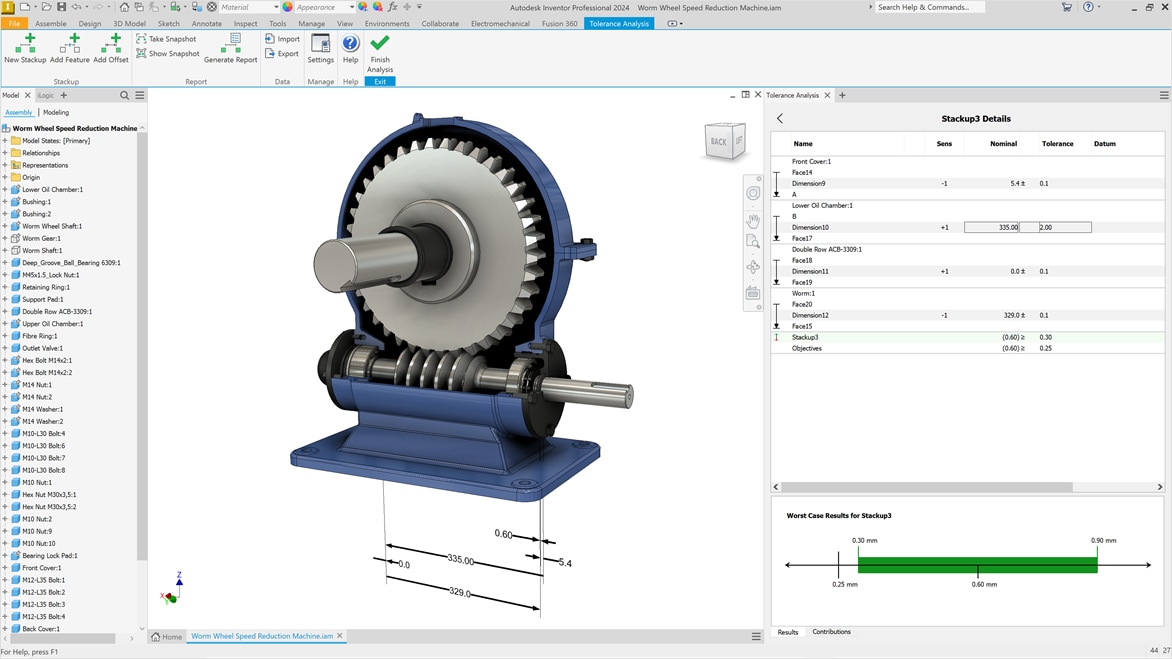

Inventor Tolerance Analysis software is designed to understand the cost impact of dimensional variation.

Integrated 2.5- to 5-axis CAD/CAM programming solution for Inventor and SOLIDWORKS—available as Inventor CAM and HSMWorks

Because model-based definition annotations are standardized and shareable between software programs, MBD eliminates the manual re-entry of data from 2D drawings—reducing errors and time spent on the design, manufacturing, and inspection processes.

Using model-based definition makes deliverables simpler and reduces response times. Engineers spend less time on design documentation and writing out less information by hand.

Carefully annotating 3D models in MBD software reduces communication errors and manufacturing prep time by embedding quality requirements into CAM software.

MBD data stays with the model throughout the design and manufacturing workflow, boosting communication and collaboration between departments.

MBD eliminates the labor and material costs associated with producing, storing, and managing 2D drawings. It also reduces waste from scraps and rework.

Heavy equipment leader Caterpillar uses MBD for its initiatives, such as these semi-autonomous construction vehicles.

Image courtesy of Caterpillar

Generative design early adopter General Motors has also adopted MBD for its design and manufacturing processes.

Image courtesy of General Motors

Xometry, an on-demand manufacturer highlights the time-saving benefits of using model-based definition and other product manufacturing information (PMI).

Image courtesy of Xometry

In the late 20th century, advancements in CAD software started to enable more detailed and precise digital models. As CAD technology improved, engineers began to see the potential of using 3D models not just for visualization, but as comprehensive sources of product information.

In the early 2000s, the aerospace industry's need for tight tolerances and precise data management accelerated the adoption of MBD. Industry leaders collaborated to establish standardized practices. This standard provided guidelines for embedding product and manufacturing information (PMI) within 3D models, enhancing communication and reducing errors.

Following the establishment of the ASME Y14.41 standard, companies began to adopt MBD practices to streamline their processes. The aerospace and automotive industries were among the early adopters, using MBD to enhance precision, reduce development times, and improve collaboration.

As technology continued to evolve, MBD software became more sophisticated, with features such as automated annotation, real-time data sharing, and integration with other digital tools like product lifecycle management (PLM) and computer-aided manufacturing (CAM) systems. This made it easier for companies to implement MBD and reap its benefits.

Today, MBD is essential to digital manufacturing strategies, aiding in the rise of model-based enterprises (MBE) that optimize operations using digital model data. Its integration with technologies like AR, VR, and AI is enabling efficient, accurate, and collaborative workflows.

The future of model-based definition (MBD) looks incredibly promising as industries continue to move toward digitalization and automation. As technology advances, MBD will likely integrate with tools like augmented reality (AR), virtual reality (VR), and artificial intelligence (AI), making it even more powerful. These technologies will allow for more interactive and user-friendly ways to work with 3D models, simplifying complex data and making it easier to understand.

MBD will also enhance global collaboration, helping teams and supply chains work together seamlessly across different locations. By streamlining processes, boosting accuracy, and cutting costs, MBD will become a key component for manufacturers aiming to stay competitive. Companies that adopt MBD will be better positioned to meet market demands and deliver high-quality products quickly and reliably.

MBD is a component of the broader MBPD approach. MBD focuses on detailed product documentation within models, while MBPD uses models to drive and optimize the entire product development lifecycle. Here's a breakdown of the key differences:

1. Scope:

2. Application:

3. Objectives:

Don’t tolerate assembly problems; this Autodesk University class shows how the Tolerance Analysis plug-in for Inventor helps you manufacture right the first time.

Learn how defining a CAD model with MBD saves time and adds value to downstream supply chain processes.

See how CAD data is consumed by production engineering and CAM systems and why center-tolerance models are a best practice for providing CAD data for manufacturing.

If you're a mechanical engineer considering whether your company should adopt MBD/PMI processes, this summary can guide you in understanding its benefits and potential for your organization

Learn the full set of capabilities available to reduce your dependence on 2D drawings and begin to digitize your design-to-manufacturing process.

With these few tips, you can easily create advanced Model-Based Definition in Inventor.

MBD is an acronym for model-based definition, which annotates a 3D model with all the vital non-geometric information needed for manufacturing and inspection, such as dimensions, tolerances, symbols, finishes, and materials. MBD is a deliverable that comes embedded within a 3D model.

Autodesk Inventor software also uses the acronym 3DA (three-dimensional annotation) synonymously with MBD.

MBD and MBE are two sides of the same model-based coin. The 3D model is the centerpiece around which design, engineering, manufacturing, and inspection processes are built.

Model-based definition (MBD) annotates a 3D model with the non-geometric information needed for manufacturing and inspection.

On the other hand, the term model-based enterprise (MBE) denotes a product development organization that has extrapolated the model-based ethos as far as possible. An MBE may use a 3D model as a single source of truth to inform decision-making and provide insights for design, engineering, internal and external supply chain processes, customer support, and more.

Product manufacturing information (PMI) includes several types of data describing a designed part or assembly, such as dimensions, tolerances, materials, and surface finishes. Model-based definition (MBD) is the technology for embedding PMI as metadata into a 3D model to eliminate the older method of conveying PMI through 2D drawings.

By including accurate PMI in a CAD model’s MBD annotations, that data is readily available as a single source of truth at every step of the product’s lifecycle.

MBD improves quality control by reducing errors in communication and manufacturing prep time, maintaining the accurate and consistent transfer of data.

Yes, MBD integrates with various digital tools like product lifecycle management (PLM) and computer-aided manufacturing (CAM) systems, for improved efficiency.

Yes, by keeping all product information in the 3D model, MBD improves communication and collaboration between departments and global teams.

MBD is particularly beneficial for industries that require tight tolerances and precise data management, such as aerospace, automotive, and manufacturing.

Yes, MBD reduces costs by eliminating the need for producing, storing, and managing 2D drawings, thus reducing waste from scraps and rework.