& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Additive manufacturing, also known as 3D printing (US Site), is a process used to create a physical (or 3D) object by layering materials based on a digital model. Unlike subtractive manufacturing, which creates its final product by cutting away from a block of material, additive manufacturing adds material to form its final product.

Additive manufacturing expedites prototyping, allowing designers, engineers and manufacturers (US Site) to quickly refine designs, saving time and reducing costs. Additive manufacturing also enables customised manufacturing and promotes sustainability through the reduction of waste and energy consumption.

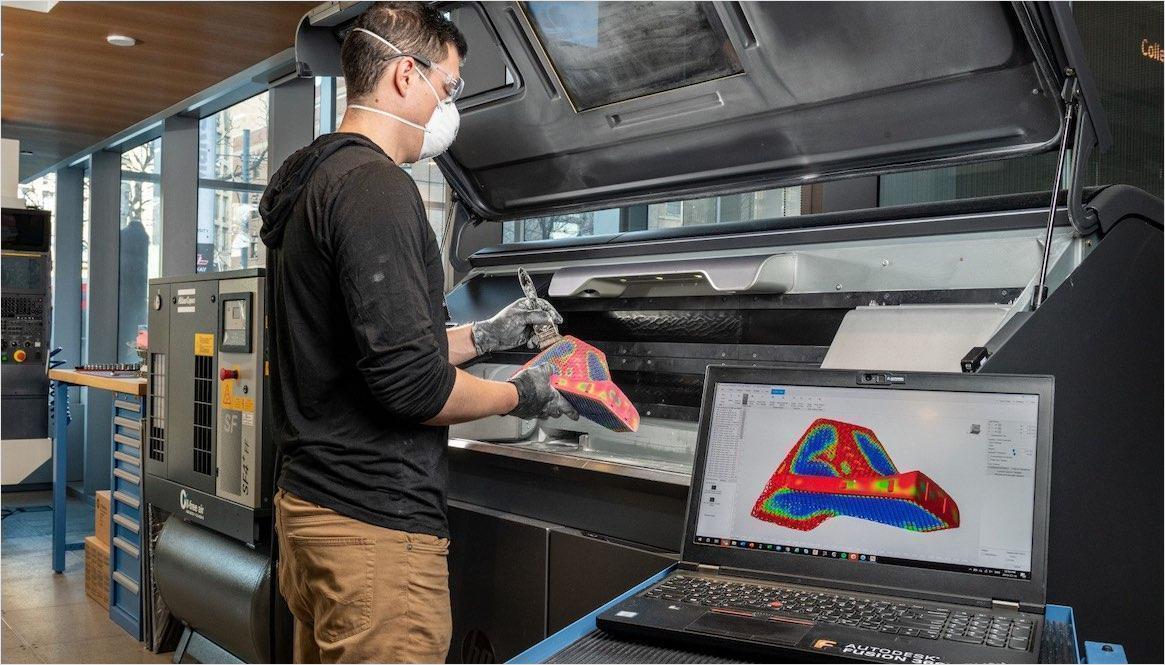

Additive manufacturing software supports and optimises the entire process of additive manufacturing. It plays a critical role in 3D printing workflows, from design and modelling to planning, slicing and machine control. The software enables creators to produce fully prepped design files and connect directly to 3D printing machines.

Additive manufacturing is primarily used by engineers, architects and construction managers, and has replaced manual drafting. Manufacturing software (US Site) helps users create designs in three dimensions to visualise construction and enables the development, modification and optimisation of the design process. This process helps engineers make more accurate representations and modify them more easily to improve design quality.

Learn about some of the top benefits of additive manufacturing.

Additive manufacturing enables the quick creation of intricate and lightweight parts. With 3D printing processes, it’s possible to create such parts as a single, durable object.

With additive manufacturing software, users can visualise designs clearly before 3D printing, instantly and efficiently testing out design alterations.

The capability to customise products helps manufacturers quickly create individual solutions for clients using additive manufacturing and 3D printing software such as Autodesk Fusion.

One of the earliest ways to use additive manufacturing for industrial purposes, this practice is now becoming an industry standard. CAD-to-additive simulation technology is improving exponentially, helping accelerate the production of lightweight components.

While prototyping is the original use of additive manufacturing, many companies are now delivering reliable 3D-printed finished goods in both commercial and industrial applications (US Site). Additive manufacturing software facilitates small production runs as needed, with no mould setup time.

By directly creating what is needed, additive manufacturing processes empower manufacturers to reduce waste. 3D printing needed parts and products close to the end user results in a more flexible and efficient supply chain.

Rapid prototyping refers to the ability to quickly 3D print a new version of a product or part. It’s part of the additive manufacturing process that can be leveraged for more effective final outcomes without expensive or time-consuming prototyping stages. Designers and engineers can use 3D printing software such as Autodesk Fusion to test out many iterations of an object, and instantly print them for testing in the real world. This streamlined additive manufacturing process ensures that any potential problems are ironed out before a launch.

Our most popular additive manufacturing software tool is Autodesk Fusion. You can use it to design a 3D model, which can then be created using additive manufacturing technologies such as multi-jet fusion, binder jetting and fused filament fabrication. Autodesk Inventor is another tool that’s particularly useful if you’re designing mechanical parts or engineering features. Using either of these additive manufacturing software options, you can design the part or product you need, save it as a file and send it to be printed using your preferred 3D printing service or your own equipment.

It’s easy to try out Autodesk’s additive manufacturing software solutions before committing. You can start a free trial of Autodesk Fusion as a home or business user, giving you time to see if the software meets your 3D printing and additive manufacturing needs.

Discover top additive manufacturing tools and features available with Autodesk software.

Software tools allow users to create or import 3D models of objects to be 3D printed. 3D modelling tools include features for precise geometry editing, parametric design and support structure generation.

Additive manufacturing software provides control interfaces for operating 3D printers, monitoring the print progress, adjusting parameters in real time and identifying issues that may arise during the printing process.

Additive manufacturing software allows users to select and customise materials and their properties, such as material type, colour, density and infill patterns.

Once 3D printing is complete, some additive manufacturing software provides recommendations for post-processing, including removing support structures, painting, sanding or applying other finishing techniques.

Additive manufacturing can encompass multiple processes, depending on the hardware, material requirements and product application.

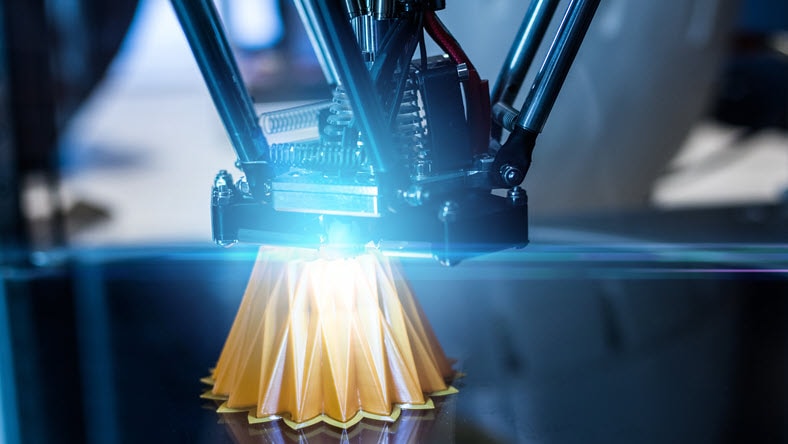

A vat of photopolymer liquid is cured by focused UV light (US Site) that builds parts layer by layer for a high-detail surface finish.

A powder substrate is hardened when the printing head deposits a drop of binding fluid in a layering process. This process allows for full-colour prototype fabrication.

In this process, used where surface finish and form testing are needed, a printhead lays down successively solidifying layers of UV-curable material to form prototyped designs.

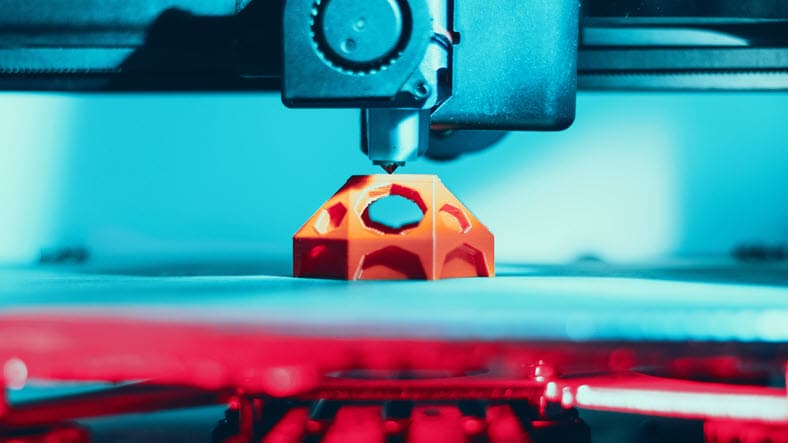

Fused deposition modelling (US Site) is a common 3D printing process in which a heated nozzle extrudes a plasticised material to form products from a sliced CAD model.

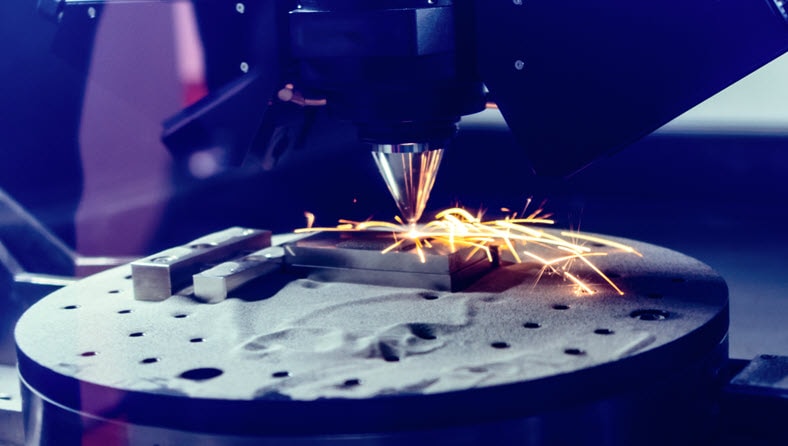

Laser or electron beams rapidly fuse layered powder material (US Site), such as various metals, together. This technique is used for circuits, structures and parts.

Ribbons of metal or paper are bonded through ultrasonic welding or adhesive, respectively. The finished shaping is completed through further material removal processes.

This process (US Site) repairs or adds to existing components by using a multi-axis nozzle to extrude laser-melted material, commonly metal powders, onto the printing surface.

Using generative design (US Site) and simulation software (US Site) to produce complex metal parts helps manufacturers get more value from proven metal casting (US Site) processes.

Discover how our customers are using Autodesk additive manufacturing software in their projects.

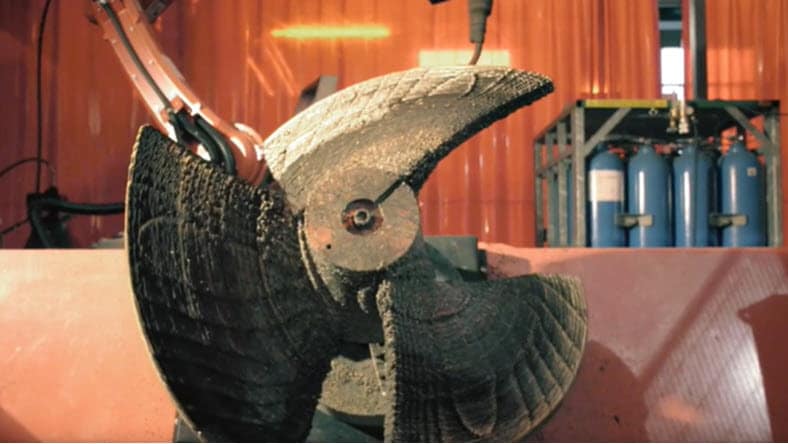

RAMLAB

The Rotterdam Additive Manufacturing Lab (RAMLAB) is pioneering the use of additive manufacturing on demand for Europe’s largest port.

General motors

General Motors is transforming car design with additive manufacturing and generative design by creating lighter, more efficient automotive parts.

Gramm

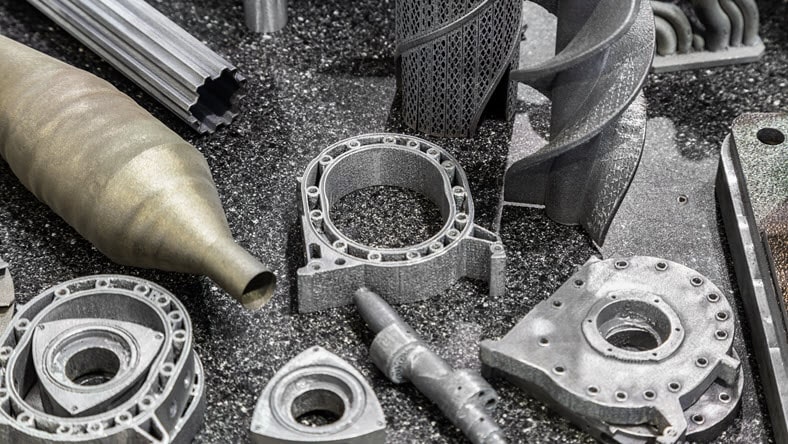

Gramm, an additive manufacturing startup, is unlocking the potential of 3D printing by printing metal tools that would have traditionally been manually crafted.

Stanley Black & Decker

Black & Decker used generative design and additive manufacturing technologies to take a new approach to improve tool design.

Learn more about additive manufacturing with these helpful resources from Autodesk.

Learn how to use Autodesk Fusion to create toolpaths and support strategies for powder bed fusion machines.

With multi-material 3D printing, you can use different materials in one printed object. This allows for different parts of the object to be made with materials selected for their specific properties, like rigidity, elasticity or temperature resistance.

Use this comprehensive list of file export types enabled in Autodesk Fusion to determine the best file format for your desired printer.

This app add-on allows you to transfer print information directly to your HP 3D printer from within Autodesk Fusion.

Learn how the team at Autodesk collaborates with industry partners to explore, identify and experiment with new applications and opportunities in the additive manufacturing space.

Learn about the general design practices that apply to all types of additive manufacturing, including metal (SLM) and polymer materials.

Learn more about additive manufacturing software with these top questions frequently asked by users.

Additive manufacturing offers several eco-friendly and sustainability benefits, including opportunities to minimise waste, optimise designs, reduce energy consumption, simplify supply chains and enable sustainable production practises.

Additive manufacturing is used to produce lighter, stronger parts and systems with much greater efficiency. It has uses across a variety of industries including:

Additive manufacturing provides several advantages for industrial use. Significantly, additive technologies produce parts that are lighter, stronger and faster to create than their traditional counterparts.

Additive manufacturing, also known as 3D printing, is the process of adding material to create an object. Machines deposit material, layer upon layer, in precise geometric shapes, and CAD software or 3D object scanners are used to create models to direct the hardware using additive manufacturing software features.

A variety of materials (US Site) are used in additive manufacturing, including metals, ceramics and glass. Each material has its own advantages and applications. Powders for 3D printing metals can range from titanium to alloys, to precious metals such as gold. Polymers (including ABS, PLA, PVA and polycarbonate) and metals (US Site) (gold, stainless steel, silver, steel and titanium) are two of the most commonly used material types. Many other materials can also be used for additive manufacturing, including ceramics, glass, resin and potentially even human cells.

3D printing is a more consumer-friendly phrase, and it’s becoming more and more popular in use than additive manufacturing. There are some subtle differences (US Site), however, and the term “additive manufacturing“ can be used to refer to other processes such as rapid prototyping, whereas 3D printing is more restrictive.

The two phrases can best be defined as: